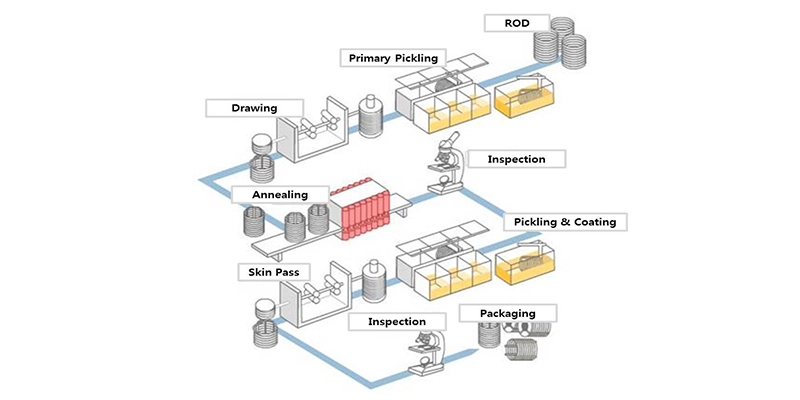

MANUFACTURING PROCESS

CHQ WIRE

- R

Raw material (ROD)

- PC

Primary pickling

- PC

Product Pickling

- RA

Annealing (Regular)

- SA

Annealing (spheroidization)

- D

Drawing

- SKP

Final Drawing (Skin Pass)

- P

Packaging

| PROCESS | Process Flow |

|---|---|

| HD | R PC SKP P |

| S)AIP | R PC SA PC SKP P |

| SAIP | R PC D SA PC SKP P |

| PASAIP | R PC RA PC D SA PC SKP P |

| PSASAIP | R PC SA PC D SA PC SKP P |

- HD : ROD → Product Pickling & Coating →

Drawing(SKP)

Hard Drawing - (S)AIP : ROD → Primary pickling → Annealing(SA) →

Product Pickling & Coating →

Drawing(SKP)

(Spheroidizing) Annealing In Process ※ ( ) : RA / LA / SA - SAIP : ROD → Primary pickling → Drawing(Primary) →

Annealing(SA) →

Product Pickling & Coating → Drawing(SKP)

Spheroidizing Annealing In Process - PASAIP : ROD → Primary pickling → Annealing(RA) →

Primary pickling →

Drawing(Primary) → Annealing(SA) → Product Pickling & Coating →

Drawing(SKP)

Pre-Annealed SAIP - PSASAIP : ROD → Primary pickling → Annealing(SA) →

Primary pickling →

Drawing(Primary) → Annealing(SA) → Product Pickling & Coating →

Drawing(SKP)

Pre-Spheroidizing Annealed SAIP

Acquired patent for CHQ WIRE Non-phosphate Coating

(Patent No. 10-1523546)

The purpose of Non-Phosphate Coating

High-strength bolts and forged products using CHQ wire treated with zinc phosphate-based coating (bonderizing) must undergo a dephosphorization process before heat treatment (QT). Non-phosphate coating CHQ wire products do not cause phosphorizing or hydrogen embrittlement because the dephosphorization process (removal of phosphate coating) is omitted before heat treatment, so there is no bursting or breaking of parts. This makes it possible to reduce process costs and produce products with almost no defect rate. In addition, the plated surface of product is very beautiful because of the process without dephosphorization.

Non-phosphate coated high strength product process

- Cooling plastic

processing

(bolt and forged

product) - Omission of dephosphorization

process - Heat treatment

process - Surface treatment

process